licat

Activity description

Licat was founded in Turin in 1961.

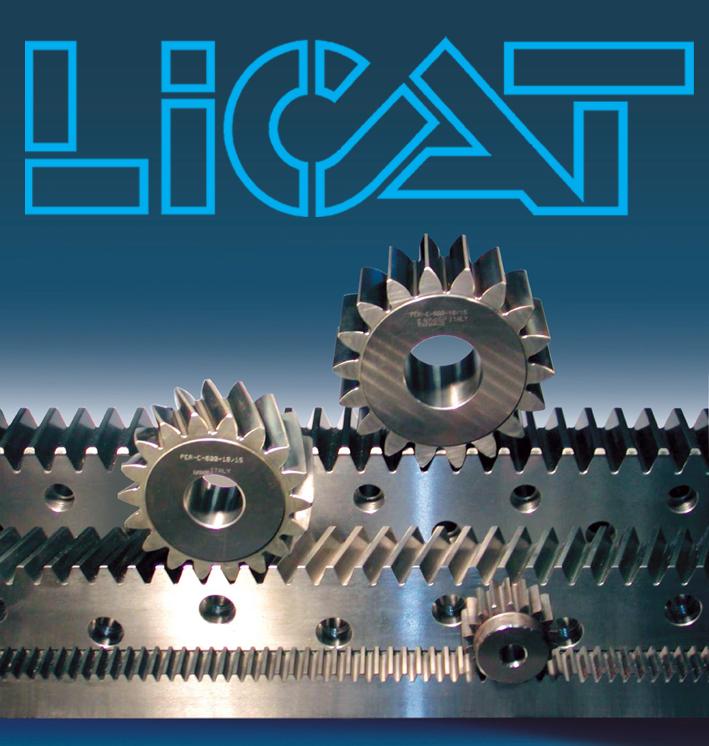

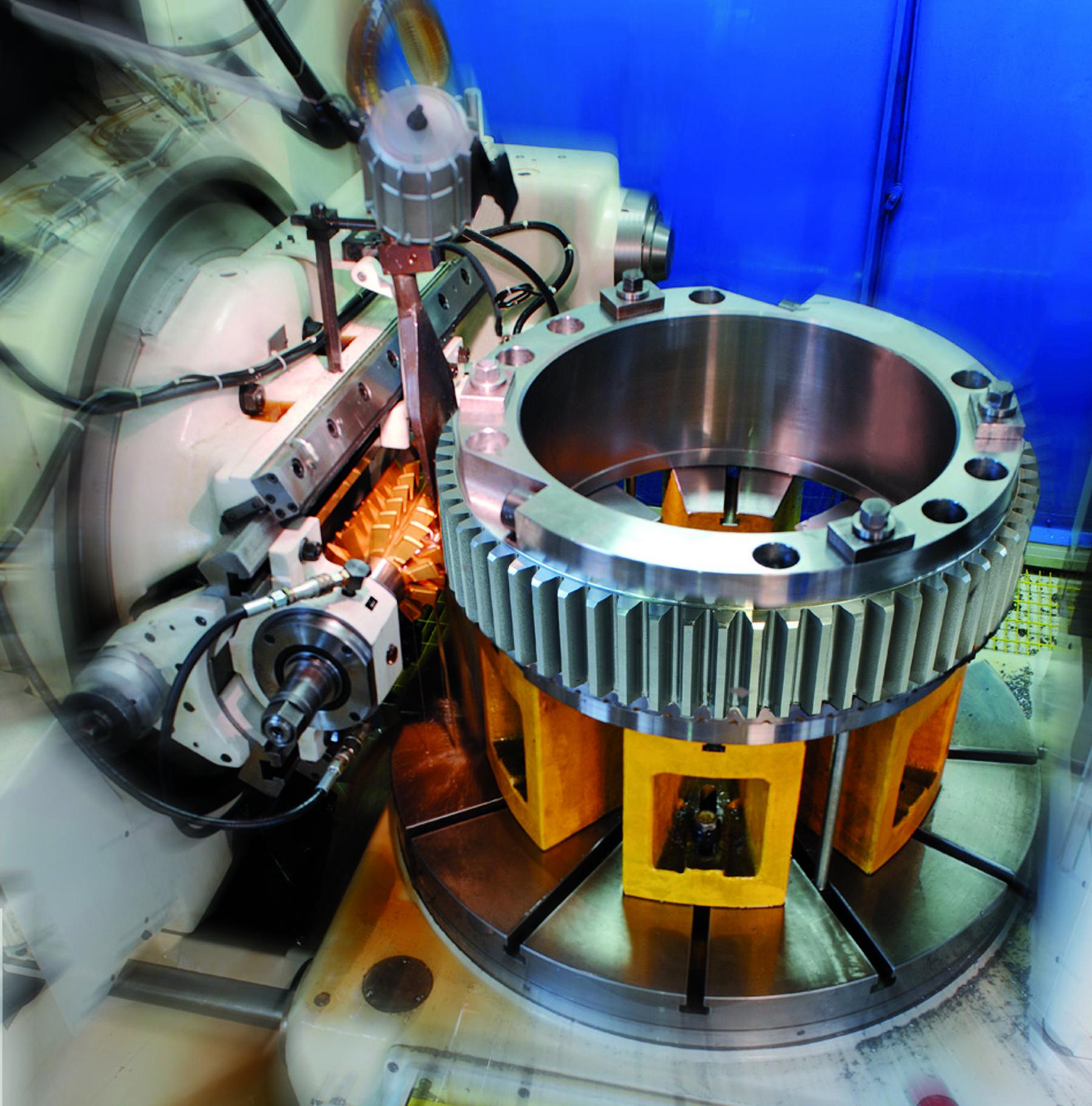

Tight internal organization, dedicated staff, and technical features of machines, make Licat a competitive supplier of high-precision gears, racks and pinions, complete solutions for linear transmission systems, worm gears, spline shafts, toothed sectors, couplings, and frontal inserts - also as a small series or as individual items.

The business fields are various, as our main customers works in Marine diesel engines for Shipyard and Power plants, Railway Diesel and Electric traction units, Military Equipment, Wind and Gas turbines, Heavy Duty Machine tools for Steel production and machining, Gantry robots and Automation equipment, Plastic forming, Measuring 3D, Papermill and Printing, Rubber and plastic injection molding, etc.

Licat can generally satisfy all customer's needs, including material supply, heat treatment, machining, and testing. Orders can also be taken for specific process operations, with material supplied by the customer.

Licat frequently works with internationally recognized organizations such as the R.I.NA., Lloyd’s Register of Shipping, American Bureau of Shipping, the Italian Navy, Italian Railways, etc. and is directly responsible for destructive / non-destructive testing and inspection, using internal personnel under the SNT regulations.

Licat also applies its own Quality Management Manual, wheras Quality complies with the ISO 9001 and EN 9100 standards.

Mechanical Subcontracting

Mechanical Machining

Standard Components

Production Systems & Automation (Machinery and Industrial Automation)

Supply / Components (for machine tools, molds, etc…)

Other key sectors

Aerospace